☰ Menu

Menu

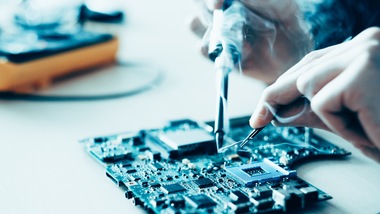

Soldering is one of the most vital skills necessary to take part in the world of PCB assembly services. By utilizing professional certification classes, a whole new realm of soldering training is opened up. Learning soldering is best accomplished by earning soldering certification through trustworthy IPC training classes, like those offered by EEI. However, before you begin your in-depth foray into solder training courses, consider reading through our 5 tips on learning this invaluable skill!

Thorough Preparation Before Soldering

Before you turn your soldering iron on, it is important to make sure that you are fully prepared. This will ensure that your work is optimized and efficient while remaining safe. Ensure that you have a heat-proof surface to work on, the correct tip for your iron, and that your soldering iron can stand safely on a heat-proof surface. Once you have these, equip your trusted safety goggles and proceed.

Learn How to Tin Your Tip

Before every soldering process, you should always tin the tip of your soldering iron. Tinning is the process of coating the surface of the tip in solder – which contains tin, hence “tinning” – to prevent oxidization. This also helps the solder stick to your tip and flow where it should. Once your iron is hot, hold it over your heat-proof surface (or cleaner if you have one), then touch your solder to the tip and cover the bottom centimeter. Then, clean the excess solder off and repeat this process until the tip is shiny.

Hold Completely Still

Every successful printed circuit board assembly requires the board to be held completely still. There are tools available that help hold your board in place as you commence your soldering, which is crucial to the safety and success of your project. Consider sticking your PCB to a board that is designed to hold it steady or use adhesive to keep your board still and level while it sticks to your heat-proof work surface.

Creating The Perfect Solder Joint

In order to manufacture the perfect solder joint, several factors need to come together perfectly. Don’t stress – instead, focus on these key variables:

Avoid These Pitfalls

As you proceed with your PCB assembly services, be wary of these red flags and learn how to prevent them:

With these easy tips for successful soldering in mind, consider enrolling in EEI’s certification classes and learning soldering with us. The technical training and business skills training offered by EEI Training are fully customizable to meet the needs of every organization we work with. Call EEI today to learn more about our technical courses!